TECHNOLOGY FOCUS

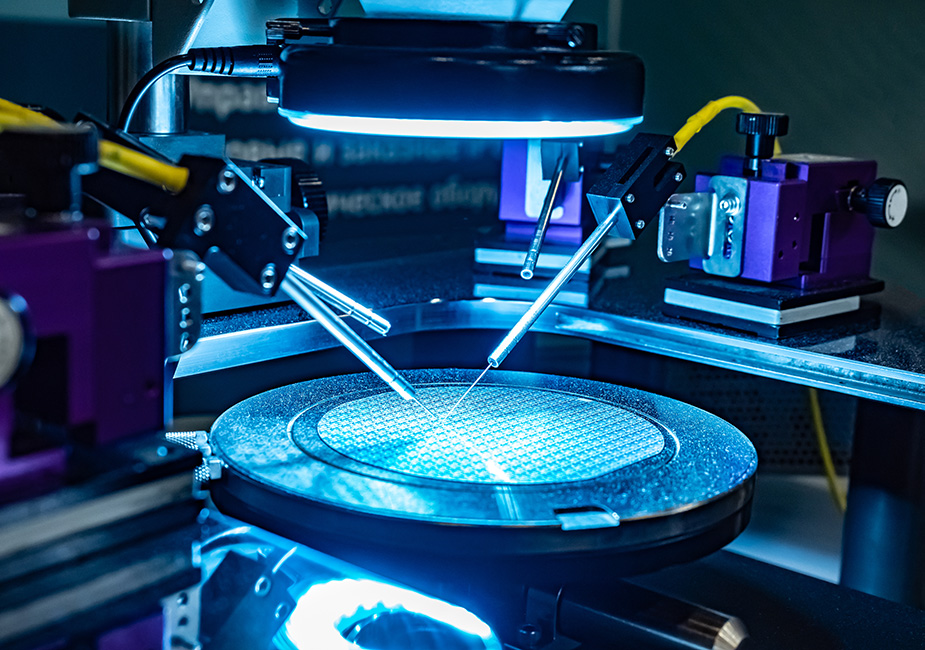

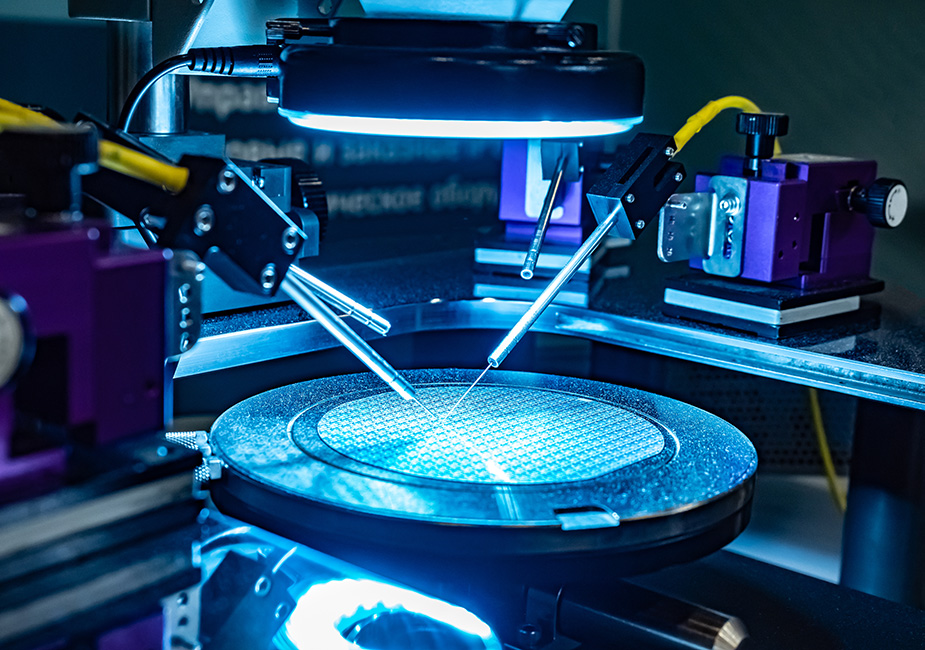

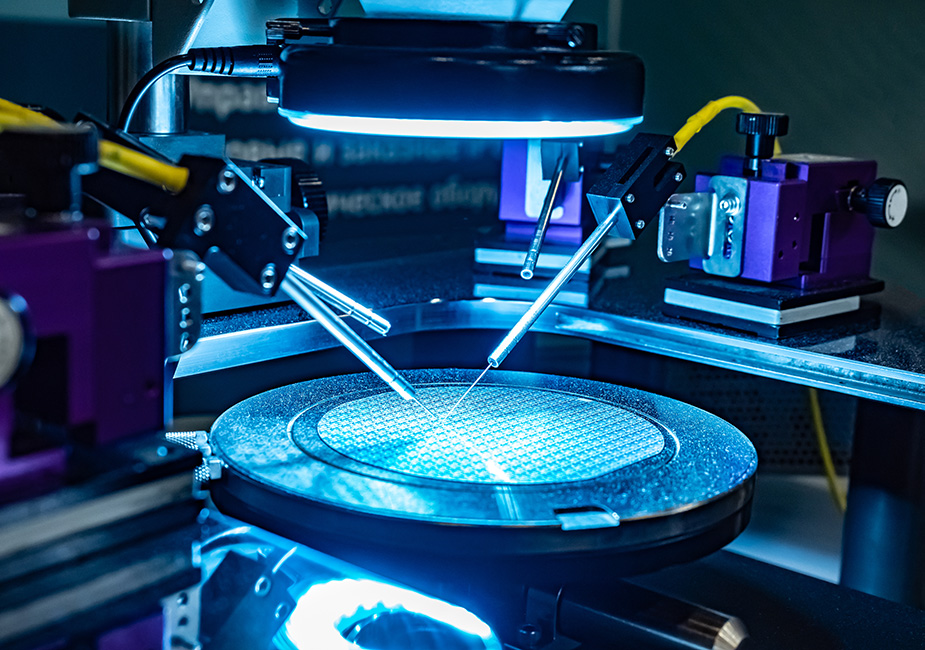

The computing power packed into a tiny microchip has exploded over the past several decades. A huge driver has been phenomenally successful continuous evolution in microchip fabrication equipment, materials and techniques. With each new generation of chips, as devices are scaled ever-tinier and performance requirements are ever more demanding, comes a wide range of exciting yet onerous new processing challenges, met head-on by highly motivated scientists and engineers.

The course is not geared to a particular technology node; it considers the wide range of fab processes and technology nodes in volume production today.

COURSE CONTENT

This 4-day course examines the entire wafer fab process, from Fab In through Parametric Test. (It also includes the details of raw Si wafer production.) Each processing technique is studied in turn. A baseline CMOS process flow is studied to introduce critical concepts of process integration. While knowledge of wafer fabrication would certainly be an asset, it is not a prerequisite. Participants will be encouraged to ask questions and to participate in brief discussions. The highly detailed course notes provided will minimize the need for note-taking during class and will serve as an excellent useful post-course reference.

WHO SHOULD ATTEND

This course is geared to a broad audience. While certainly technical in nature, it aims to also be highly practical, with a minimum of complex math and physics. Past participants have included scientists, engineers and technologists from a wide range of wafer fab equipment and materials supplier companies. Participants from wafer fabs have included process engineers, equipment engineers, yield engineers, process integration engineers, product engineers and technical managers.

Daily Schedule

The course material is arranged into 20 modules, five per day:

Module 1: Basics and Fundamentals; Semiconductor Devices and ICs

Initialisms and Acronyms

The Language of Wafer Fab

Brief History (e.g., evolution of electronic devices and ICs; scaling)

Electrical Conductivity

Semiconductor Devices (diodes, resistors, capacitors, transistors, MOSFETs)

Common CMOS Device Problems

Classification of ICs and IC Processes

Integrated Circuit Types

The Global Semiconductor Market

Module 2: Si Crystallinity, Crystal Defects, Crystal Growth

Crystallinity

Crystal Defects

From Sand to Silicon Wafer

Controlling Crystal Defects

Module 3: Baseline CMOS Process Flow

Summary of Wafer Fab Process Techniques

Baseline CMOS Process Flow (step by step)

Process Evolution

Module 4: Doping and Ion Implantation

Doping Fundamentals

Ion Implantation Fundamentals

Dopant Profiles

Crystal Damage & Annealing

Implant Equipment

Process Challenges

Process Monitoring & Characterization

Newer Doping Techniques

Module 5: Thermal Processing

Overview of Thermal Processing

Process Applications of SiO2

Thermal Oxidation

Thermal Diffusion

Thermal Annealing

Thermal Nitridation

Process Control

Thermal Processing Equipment

Newer Process Techniques (e.g., LSA, SPE, PO)

Module 6: Contamination Monitoring and Control

Forms and Effects

Sources and Control

Characterization and Measurement

Module 7: Wafer Cleaning and Surface Preparation

Wafer Cleaning Strategies

Chemical Cleaning

Aqueous Chemical Cleaning Equipment

Mechanical Cleaning

Newer Techniques (e.g., SCCO2, MD)

Module 8: Thin Films

Definitions

Film Formation Techniques

Important Properties

Metrology

Module 9: Vacuum Fundamentals, Plasma Fundamentals

Gas-Solid/Liquid Interactions

Vacuum Pumps

Wafer Fab Vacuum Systems

Plasma Basics

DC Diode Glow-Discharge Plasma Source

RF and HD Plasma Sources

Module 10: CVD 1: Basics, LPCVD, Epitaxy

CVD Basics

LPCVD Films

LPCVD Nitride/Poly Deposition Equipment

Epi Basics

Epi Process Applications

Epi Deposition Process

Epi Deposition Equipment

Module 11: PVD

PVD (Physical Vapour Deposition) Basics

Sputter Deposition Process

PVD Equipment

Step Coverage and Contact/Via Hole Filling

Metal Film Evaluation

Electrostatic Chucks

Module 12: Lithography 1: Photoresist Processing

Basic Lithography Process

Photoresist Materials

DUV Photoresist Process Flow

Photoresist Processing Systems

Module 13: Lithography 2: Image Formation

Basic Optics

Imaging

Overview of Imaging Equipment

Actinic Illumination

Exposure Tools

Module 14: Lithography 3: Registration, Reticles, RETs

Registration

Reticles

Resolution Enhancement Techniques (RETs)

The Evolution of Optical Lithography (EUV)

Module 15: Etch

Etch Terminology

Wet Etch Chemistries and Equipment

Dry Etch Processes

Physics and Chemistry of Plasma Etching

Dry Etch Applications

Dry Etch Equipment

Module 16: CVD 2: PECVD

CVD Basics

PECVD Equipment

CVD Films

Step Coverage

Module 17: CMP

Planarization Basics

CMP Basics

CMP Processes

Process Challenges

Equipment

Process Control

Module 18: Process Evolution 1 (Bulk Metals, IMDs); Cu ECD

Process Evolution

Al-based Interconnect

The Need for Cu and low-k IMDs

Damascene Process

Cu ECD

Low-κ IMDs

Cu Integration Challenges

Next Generation Metals

Module 19: Process Evolution 2: Gate Dielectrics, Silicides, Gates

Process Evolution

Evolution of Gate & Capacitor Dielectrics

Evolution of Silicides

Evolution of Transistor Gates

Module 20: ALD, finFETs, Misc. Processing Techniques

Atomic Layer Deposition (ALD)

Silicon on Insulator (SOI) Technology

Strained Silicon

FinFETs and Other Non-traditional Transistor Designs

3-D NAND Flash Memory

Wafer Fab’s Environmental Footprint